Home

About rendering

About rendering

Turn animal by-products into high valuable proteins and Fats

Nutrient management

Rendering is about creating the most value from animal by-products. Mavitec’s rendering solutions create the best nutrient values in the market. From poultry to red meat, we turn animal by-products into high quality end-products such as meat and bone meal, poultry meat meal, feather meal, blood meal, whole meal, tallow, fat and oil. These highly valuable ingredients are used in e.g. pet food industry, feed industry, feed industry (meals), oleochemical or cosmetics industry (fats, oil). That’s why we say: rendering is not waste handling, it’s nutrient management!

Input & output

Create the best nutrient values

Mavitec’s rendering systems recycle animal by-products that are not intented for human consumption, such as poultry by-products, red meat by-products and fish by-products. The way of processing determines the value of the end-products. After rendering, the materials are much more resistant to spoiling. The bone and protein becomes dry particles known as meat and bone meal. Mavitec creates the following high value end-products:

• Meat and bone meal

• Poultry meat meal

• Feather meal

• Blood meal

• Whole meal

• Tallow, fat and oil

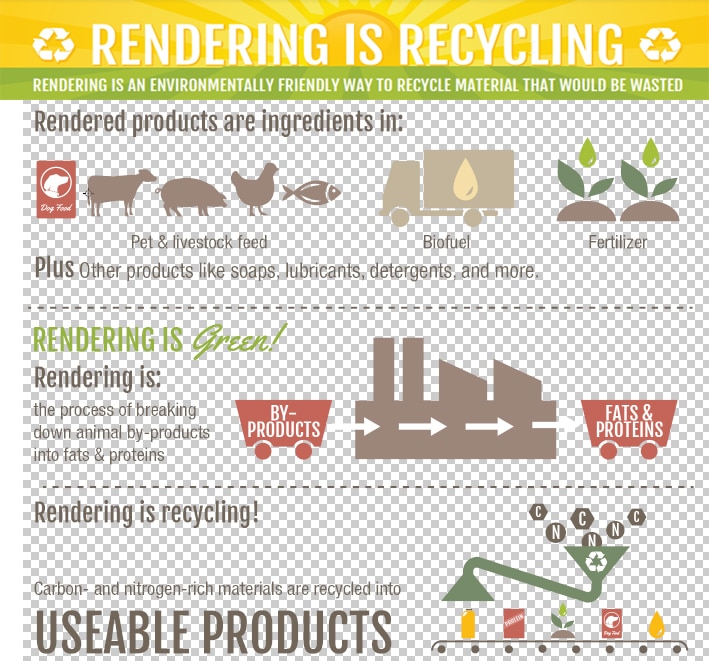

Rendering is recycling

Rendering is an environmentally friendly way to recycle material that would otherwise be wasted. Rendering is a process that repurposes by-products that would otherwise go to waste from the “meat we don’t eat.” By rendering specific materials that many North American consumers would consider inedible, such as certain fats, bones and proteins, renderers provide clean and safe rendered material used to develop sustainable new products while reducing overall food waste (source: NARA.org). The rendering industry processes most animal by-products from the meat production chain which do not end up on the consumer’s plate. These vary from country to country and depend on the eating habits of different cultures. In the western world, almost one third of the weight of animals is slaughtered. State-of-the-art technology, strict regulation and sense of commitment and responsibility for the environment mean that today’s rendering operations are highly technical and require high levels of investment. In the absence of the rendering industry, the cost of waste disposal of waste animal material would be very high and would place a significant economic and environmental burden on areas involved in industrial scale slaughtering.

Rendering is safe & essential

Benefits of rendering

Without the rendering industry, the cost of waste disposal of waste animal material would be very high and would place a significant economic and environmental burden on areas involved in industrial scale slaughtering.

• Helps food recovery hierarchy by recycling animal by-products

• Converts animal by-products into high value ingredients

• Recovered resources have high economic value

• Increasing energy independence

• It helps reduce greenhouse gases

Turn animal by-products into high valuable proteins and Fats

HISTORY of Rendering

The rendering industry is one of the oldest recycling industries. The rendering industry takes materials that would be wasted and makes useful products such as fuels, soaps, rubber, plastics, etc. Rendering solves what would be a major disposal problem. Although rendering as an organised and cohesive industry has been around for 150 years, the process of melting down animal fats to produce tallow and other fats and oils probably started when man began cooking meat over a campfire and saving the drippings. Historians have charted soap and candle-making from the products of rendering, with one of the first accounts of rendering being written by a Roman soldier. In recent times, the industry has made an important contribution to a clean and healthy environment. In addition, it turns unusable materials into usable commodities, for example tallow for soap production, base chemicals and animal protein for livestock nutrition.

Economic impact

Other major factors which impacted the industry in the 20th century were the popularization of chemical fertilizers, the development of synthetic detergents, the widespread adoption of “boxed beef” in the USA, and the change in consumer eating habits to reject animal fats. In the early 20th century the low cost of synthesis of artificial nitrogen fertilizers undermined the economic use of animal waste to enrich soils. This resulted in the loss of a substantial market for meat by-product solids. This lost market was replaced by the realisation that these products made good feed for animals. After World War II synthetic detergents came on the scene which eventually displaced soaps for both domestic and industrial washing uses. Thus, in the early 1950′s over 50% of the inedible fat market disappeared. Diversion in these materials into animal feeds soon replaced the lost soap market and eventually became the single largest use for inedible fats.

The development of rendering was primarily responsible for the profitable utilization of meat industry by-products, which in turn allowed the development of a massive industrial-scale meat industry that made food more economical for the consumer. Rendering has been carried out for many centuries, primarily for soap and candle making. The earliest rendering was done in a kettle over an open fire. This type of rendering is still done on farms to make lard (pork fat) for food purposes. With the development of steam boilers, it was possible to jacket the kettle to make a higher grade product and to reduce the danger of fire. A further development came in the nineteenth century with the use of the steam “digester” which was simply a tank used as a pressure cooker in which live steam was injected into the material being rendered. This process was a wet rendering process called ‘tanking’ and was used for both edible and inedible products, although the better grades of edible products were made using the open kettle process. After the material was ‘tanked’, the free fat was run off, the remaining water (‘tank water’) was run into a separate vat, and the solids were removed and dried by both pressing and steam-drying in a jacketed vessel. The tank water was either run into a sewer or it was evaporated to make glue or protein concentrate to add to fertilizer. The solids were used to make fertilizer.

Technological innovations came rapidly as the 20th century advanced. Some of these were in the uses for rendered products and others were in the rendering methods themselves. In the 1920′s, a batch dry rendering process was invented, in which the material was cooked in horizontal steam-jacketed cylinders that were similar to the fertilizer dryers of the day. Advantages claimed for the dry process were economy in energy use, a better protein yield, faster processing, and fewer obnoxious odours attending the process. Gradually, over the years, the wet ‘tanking’ process was replaced with the dry process, so that by the end of World War II, most rendering installations used the dry process. In the 1960′s, continuous dry processes were introduced by The Dupps Company, one using a variation of the conventional dry cooker and the other making use of a mincing and evaporation process to dry the material and yield the fat. In the 1980′s high energy costs popularized the various “wet” continuous processes. These processes were more energy efficient and allowed the re-use of process vapours to pre-heat or dry the materials during the process.