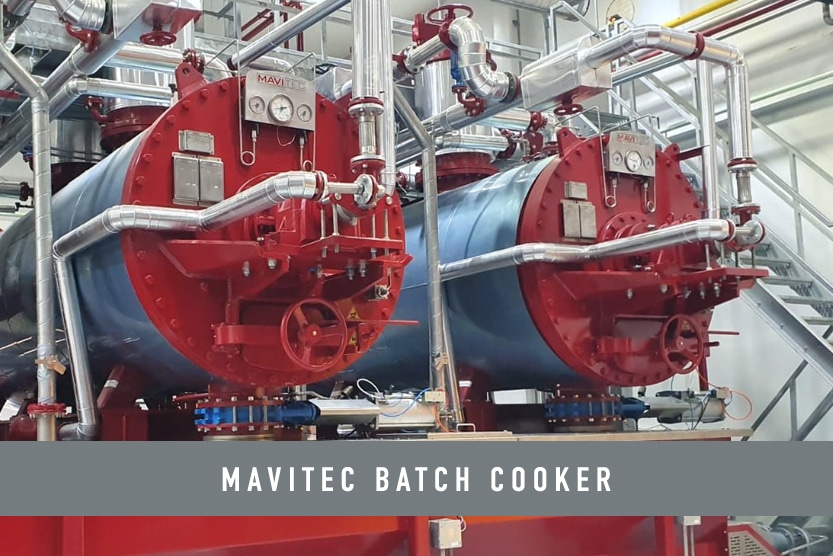

Did you know Mavitec’s batch cooker can handle capacities from 1.000 kg up to 10.000 kg/batch?

Due to the special design of shaft and shell, our batch times are on average 1 – 2 hours shorter than standard batch cooker designs, resulting in saving energy costs and higher protein levels.

For example, batch times based on full load including loading + discharge:

– Red meat: 1,5 – 2 hrs

– Soft poultry: 2,5 – 3 hrs

– Mixed: 4 – 4,5 hrs (including hydrolyzation step)

– Feathers: 4 – 4,5 hrs (including hydrolyzation step)

The function of the batch cooker in the rendering process is conditioning, sterilizing, hydrolyzing and drying of the product.

Whether your company renders white meat (poultry), red meat, feathers, blood or a mixture of by-products, Mavitec’s batch cooker is the perfect solution.

Want to create the best nutrient values in the market?

Contact us for more information and possibilities.