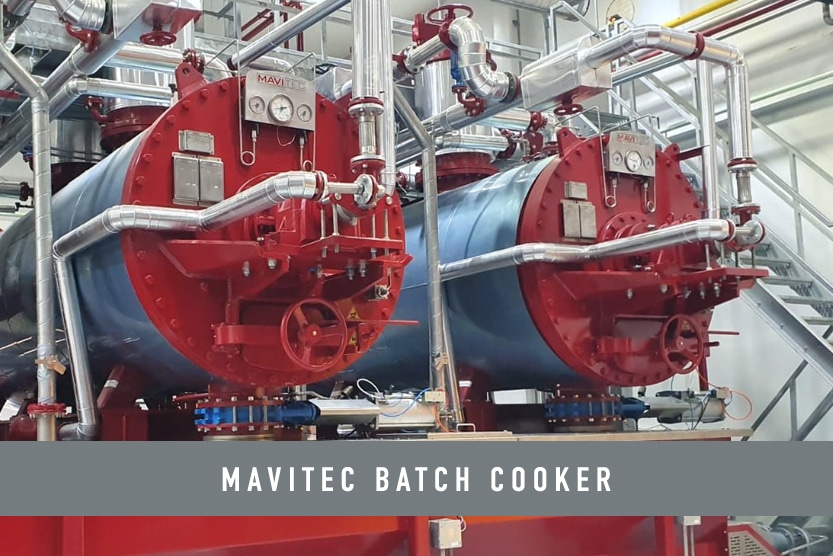

Wussten Sie, dass Mavitec's Chargenkocher Kapazitäten von 1.000 kg bis zu 10.000 kg/Charge bewältigen kann?

Aufgrund der speziellen Konstruktion von Schacht und Mantel sind unsere Chargenzeiten im Durchschnitt 1 - 2 Stunden kürzer als bei herkömmlichen Chargenkochern, was zu einer Einsparung von Energiekosten und einem höheren Proteingehalt führt.

Zum Beispiel Chargenzeiten auf der Grundlage von Volllast einschließlich Beladung und Entladung:

- Rotes Fleisch: 1,5 - 2 Stunden

- Weiches Geflügel: 2,5 - 3 Stunden

- Gemischt: 4 - 4,5 Stunden (einschließlich Hydrolyseschritt)

- Federn: 4 - 4,5 Stunden (einschließlich Hydrolyseschritt)

Die Funktion des Chargenkochers im Tierkörperverwertungsprozess ist die Konditionierung, Sterilisierung, Hydrolyse und Trocknung des Produkts.

Ganz gleich, ob Ihr Unternehmen weißes Fleisch (Geflügel), rotes Fleisch, Federn, Blut oder eine Mischung von Nebenprodukten verwertet, der Mavitec Batch Cooker ist die perfekte Lösung.

Möchten Sie die besten Nährstoffwerte auf dem Markt schaffen?

Kontakt für weitere Informationen und Möglichkeiten.