In the heart of Slovenia, Mavitec has successfully completed an advanced expansion of the existing rendering facility, at a leading European poultry processor. This project highlighted our expertise in delivering integrated, turnkey solutions that seamlessly interface with existing processes and infrastructures.

Challenge

The task involved expanding the existing rendering facility, linked to a slaughterhouse with an adjacent rendering plant. A significant challenge was integrating with existing equipment and building and synchronizing new lines with the customer’s already operational systems.

Solution

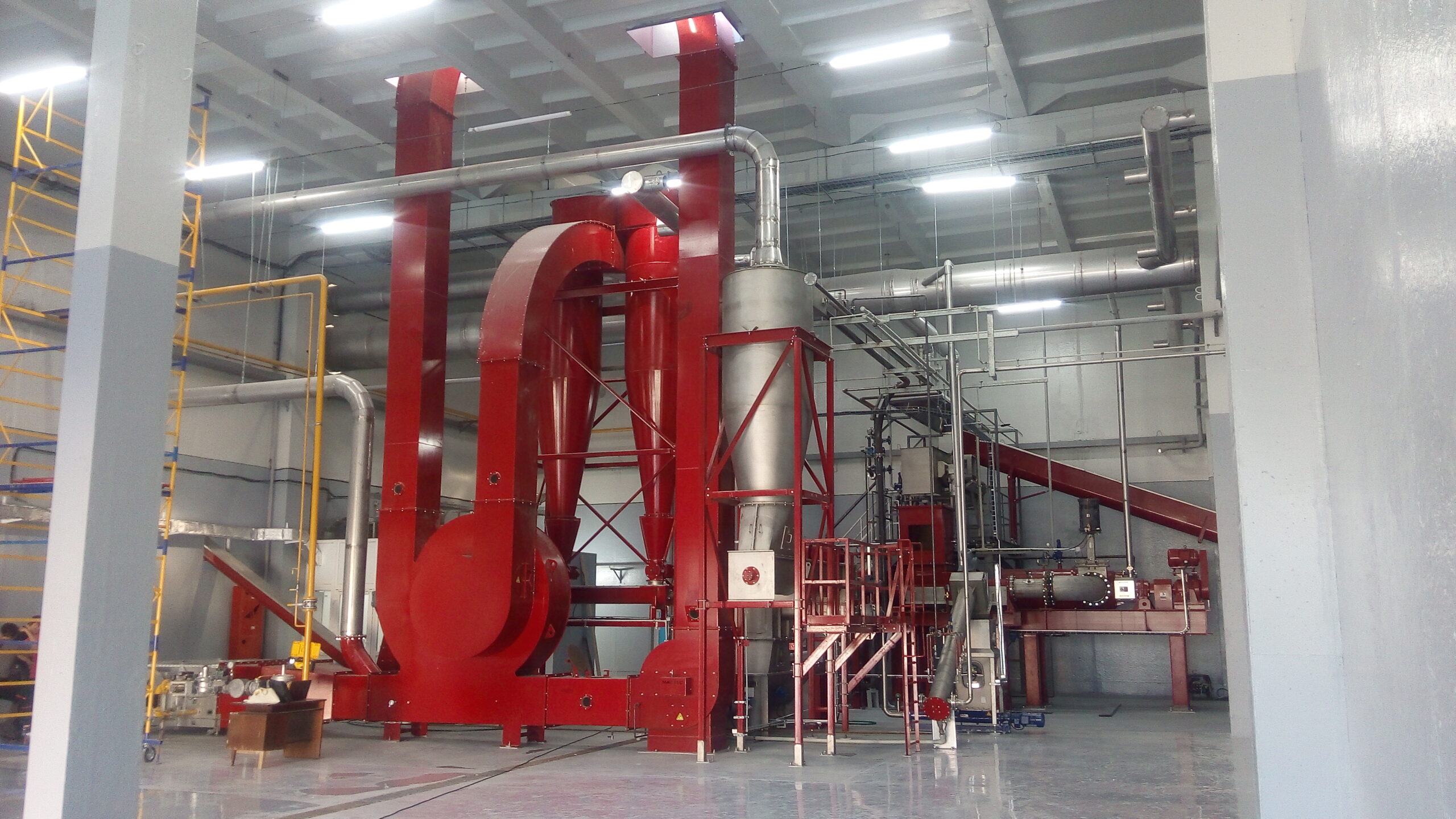

The project included the implementation of a Ring dryer line designed specifically for processing blood and feathers, significantly increasing processing capacity. The installation was delivered turnkey. We took into account existing interfaces, such as existing bins, tanks and air filtration system. The result is a line that is able to process the entire daily production of feathers and blood from the slaughterhouse, as well as locally collected materials.

Innovation

A core aspect of this project was a custom SCADA system, developed together with a local partner, to manage all equipment including all existing equipment. This ensured that our customer maintained full control over the production process, in line with their desire to use their own, customized systems.

Outcome

The new installation not only increased production efficiency but also ensured a more robust operational workflow, allowing the customer to maintain and expand its leading position in the industry. This project underscores Mavitec’s capacity to effectively integrate and optimize complex industrial installations.

Future Vision

This project lays the groundwork for further collaboration with our customer, with future expansions and technological upgrades already in preparation. Mavitec remains committed to innovation and sustainability in the agro-industrial sector.